What Is Shot Peening?

Shot peening is a surface treatment process used to strengthen metal components and improve their performance over time. The process works by bombarding the surface with small spherical media, creating a layer of compressive stress. This added stress helps prevent fatigue cracks and slows the effects of wear and corrosion.

At Halo Metal Prep, we use advanced shot peening equipment to ensure consistent, controlled results. Every component we treat is enhanced for durability, reliability, and long-term performance. By applying shot peening, manufacturers reduce the risk of premature failure and extend the usable life of critical parts.

With more than 40 years of experience, Halo Metal Prep has developed proven methods for applying shot peening to a wide variety of applications. Our focus is on delivering results that strengthen metal surfaces, improve resistance to damage, and provide confidence in the performance of each part.

The process is akin to hammering the surface with numerous tiny hammers, stretching the surface and embedding it with a compressive stress layer. This method not only extends the lifespan of metal components but also markedly improves their strength and fatigue resistance.

Shot Peening Process

Key to industries requiring resilient metal parts, shot peening involves choosing the right shot media and propelling it at high speeds towards the metal surface. This precise process, customizable to specific material needs, significantly alters surface properties for enhanced durability.

Each shot acts as a tiny peening hammer upon impact, deforming the surface in a controlled manner. This deformation leads to the formation of a compressive stress layer, crucial for improving the material’s mechanical properties. Precise control over shot size, velocity, coverage, and intensity is essential to ensure optimal results and avoid surface damage.

Purpose of Shot Peening

The purpose of shot peening extends beyond merely enhancing material strength. It plays a pivotal role in mitigating the adverse effects of tensile stresses introduced through manufacturing processes like machining, welding, and heat treatment. These tensile stresses can significantly reduce a component’s resistance to fatigue and stress-corrosion cracking.

By introducing a compressive stress layer on the surface, shot peening counteracts these detrimental tensile stresses, thereby enhancing the component’s overall durability and performance. This makes shot peening an indispensable technique in numerous industrial applications aiming to improve the longevity and reliability of metal components.

Shot Peening Advantages

Shot peening offers a multitude of benefits, particularly in enhancing the durability and performance of metal components. One of its primary advantages is the significant improvement in fatigue resistance. This process effectively delays the initiation and propagation of cracks in high-stress components, thereby extending their service life. Furthermore, shot peening increases the part’s resistance to corrosion and stress-corrosion cracking, making it invaluable in harsh operating environments.

Additionally, this process can induce beneficial residual stresses in the surface layer of treated components, which is particularly advantageous for parts subjected to cyclic loading conditions. By modifying the surface properties without altering the component’s overall dimensions, shot peening also allows for the maintenance of tight manufacturing tolerances. This dual benefit of enhanced mechanical properties and maintained dimensional accuracy ensures that shot peening remains a preferred treatment method in precision engineering applications.

Shot Peening Applications

Beyond significantly enhancing durability and fatigue resistance, shot peening is widely applied to strengthen critical components across many sectors. Its ability to extend service life, prevent cracking, and improve performance makes it a versatile and essential process in modern manufacturing.

Additionally, shot peening is widely used on precision components to ensure reliability and long service life. The process is also employed in the energy sector, particularly in treating parts for wind turbines and other high-demand equipment, where failure can have significant consequences. The broad applicability of shot peening underscores its importance in manufacturing durable, high-performance components across a diverse range of applications.

Shot Peening Services

Recognizing the critical role of shot peening in enhancing component durability and performance, many companies offer specialized shot peening services. These services are tailored to meet the specific needs of different industries and applications, ensuring that components receive the appropriate treatment to achieve desired outcomes. Service providers employ state-of-the-art equipment and techniques, along with a deep understanding of material science, to deliver optimal results.

Shot peening services encompass a range of treatment options, from standard shot peening to more advanced processes like laser peening, depending on the application’s requirements. By partnering with experienced service providers, manufacturers can leverage the full benefits of shot peening, ensuring their components achieve the highest standards of durability and performance. As industries continue to evolve, the demand for specialized shot peening services is expected to grow, reflecting the process’s integral role in modern manufacturing and engineering solutions.

Shot Peening Companies

In the realm of manufacturing and component treatment, leading shot peening companies, like us at Halo Metal Prep, have established ourselves as pioneers in the shot peening industry. We stand out for their technological innovations, comprehensive service offerings, and unwavering commitment to quality. By constantly pushing the boundaries of what’s possible with shot peening, shot peening companies help extend the life expectancy and performance of critical components across various sectors.

Our expertise not only lies in the application of shot peening techniques but also in their deep understanding of material science and engineering principles, ensuring that every treated component meets stringent industry standards.

How Does Shot Peening Improve Fatigue Life?

The science behind shot peening’s ability to improve the fatigue life of metal components is both fascinating and complex. By bombarding the surface of a component with shots, the process introduces compressive residual stress. This stress acts as a counterbalance to the tensile stresses that occur during the operation of the component, which are a primary cause of fatigue failure.

The introduction of compressive stress through shot peening effectively puts the surface of the metal in a state of compression. This state inhibits the formation and propagation of micro-cracks, which are the precursors to fatigue failure. The depth and magnitude of the compressive layer induced by shot peening are critical factors that determine the extent of fatigue life improvement. It’s a meticulous balance, as the process must be aggressive enough to create a significant protective layer without compromising the structural integrity of the component.

Furthermore, shot peening modifies the surface texture, potentially improving contact properties and resistance to surface-initiated failures. This dual action of stress modification and surface enhancement significantly extends the operational lifespan of components, making shot peening an indispensable tool in the maintenance and manufacturing of durable metal parts.

Shot Blasting vs. Shot Peening

While shot blasting and shot peening may sound similar and involve the projection of media at high speeds toward a target surface, their purposes and outcomes are distinctly different. Shot blasting is primarily used for cleaning metal surfaces, removing surface contaminants, rust, and scale to prepare a part for further processing or coating. It’s an aggressive process that can alter the surface profile and is mainly concerned with achieving a clean, rough surface for adhesion.

Shot peening, on the other hand, is a more controlled process aimed at improving the mechanical properties of the surface, specifically to enhance fatigue resistance and strength. Unlike shot blasting, shot peening does not significantly remove material from the surface. Instead, it works by inducing beneficial compressive stresses and modifying the microstructure of the surface layer.

Understanding the differences between these processes is crucial for manufacturers to ensure that the correct treatment is applied for the desired outcome. While both play important roles in the treatment and finishing of metal components, their applications and effects on the material are tailored to meet very different engineering and manufacturing objectives.

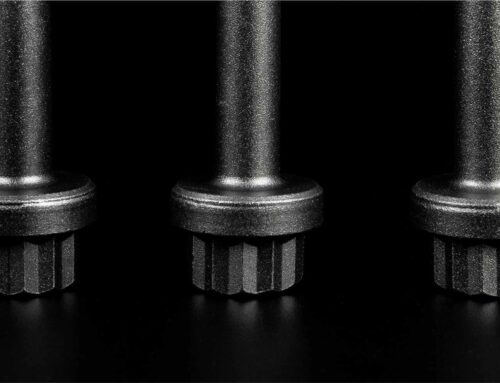

Before and After Shot Peening

The transformation that components undergo through shot peening is not just microscopic but can also be visibly discerned in many cases. Before shot peening, metal surfaces may show signs of manufacturing stresses, slight imperfections, or a polished finish, which, while aesthetically pleasing, might not be optimal for fatigue resistance. The microscopic landscape of such a surface would reveal tensile stresses lurking beneath, ready to propagate cracks under cyclic loading conditions.

After undergoing shot peening, the same component showcases a uniformly dimpled surface texture. These dimples are the external signs of the compressive stresses that now dominate the surface layer of the metal, providing a bulwark against the initiation and growth of fatigue cracks. Beyond the visible changes, the microstructural transformation within the material significantly enhances its mechanical properties. The surface becomes more resistant to crack initiation and propagation, substantially improving its fatigue life and overall durability.

This visual and structural transformation underscores the value of shot peening in extending the service life of critical components. It’s a testament to the process’s effectiveness in enhancing the performance of metals subjected to extreme operational stresses.

Shot Peening Testing Services: Almen Strip Test

The Almen strip test is a crucial technique used at Halo Metal Prep to measure the effectiveness of our shot peening process. This test utilizes a standardized steel strip to gauge the compressive forces applied during peening. By assessing the curvature induced on the strip, our technicians can precisely adjust peening parameters, ensuring optimal treatment of each component.

Employing the Almen strip test allows us to maintain high-quality standards and consistent results. This accuracy is vital for industries requiring enhanced durability and fatigue resistance in their metal components.

Choose Halo Metal Prep For Shot Peening

Shot peening stands as a testament to the ingenuity of surface engineering, offering a solution to one of the most pervasive challenges in material science: combating the effects of fatigue. Through the strategic application of mechanical stress, shot peening equips metals with the resilience needed to withstand the rigors of high-stress environments. Its application spans across various industries, highlighting its versatility and essential role in modern manufacturing processes.